|

Index...

|

good fiend of mine, John Jostins, went to the Coventry College of Art in the late 1960s, the same time as I also was studying there. However, I did not get the chance to know him very well as I was on different course studying illustration and design, while he was studying Fine Art. I did get to know him much later, though, while I was working at the Coventry Transport Museum. At the end of John's final year he exhibited various mechanical moving pieces. They were strange and took on a life of their own, powered by clockwork and electrical motors, mainly made from scrap. When John left Art School he got a job working for a company who made props for Pinewood studios.

good fiend of mine, John Jostins, went to the Coventry College of Art in the late 1960s, the same time as I also was studying there. However, I did not get the chance to know him very well as I was on different course studying illustration and design, while he was studying Fine Art. I did get to know him much later, though, while I was working at the Coventry Transport Museum. At the end of John's final year he exhibited various mechanical moving pieces. They were strange and took on a life of their own, powered by clockwork and electrical motors, mainly made from scrap. When John left Art School he got a job working for a company who made props for Pinewood studios.

The job that the company got for him was right up his street. One of his first jobs was for a low budget science fiction movie, and they wanted some robots or droids that looked used and could be made from scrap parts. John worked on and made moulds for eight R2D2s in the company workshops at Whitney in Oxfordshire. Two of the R2D2s were built to house the actor Kenny Baker, three of them were remote control R2D2s with motors, for use in the corridors in action shots, and the other three were essentially to be blown up! John was paid for his work and that was that. Not thinking much about it he then carried on with the other interests in his life, like the music scene in Coventry, as he was a big friend of Jerry Dammers and all the lads in the 'Specials', a Two-Tone band who mix Jamaican reggae with Ska music and giving it its own Coventry feel.

The science fiction movie turned out to be one of the biggest films of the 1970s - Star Wars! John did other work for science fiction programmes, such as the Dennis Potter's last film Cold Lazarus (BBC and Channel 4), a science fiction film set 300 years in the future.

When I first got to know John he was working on a prototype for an ecologically friendly vehicle called 'Microcab'. He had been awarded £45,000 to develop a fuel cell powered version of the vehicle - an ultralight urban rickshaw taxi for one driver and two people. I displayed it in the Museum around 2002.

John had taken the concept that not all countries have resources such as oil and coal, but most countries, especially island countries, do have sun, wind, rain and waves, which can all be used to create electricity. The big problem is the storage of the electricity - you get a glut during daylight hours but mainly require it in the evening. To store electricity you can charge up batteries, but they are very expensive and not very eco-friendly with all the acid and lead that goes into their production.

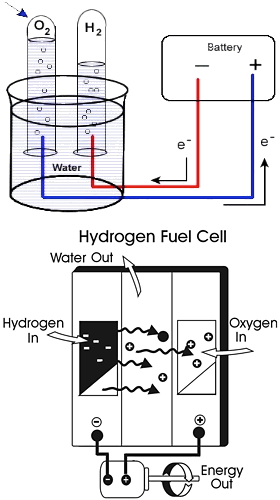

One way of storing energy is to use the electricity to make hydrogen and oxygen. It's a simple process - you just put two copper plates into a bowl of water and connect them to an electricity supply, and as electricity passes from one plate through the water to the other plate, small bubbles start forming on the plates and float to the surface. This is the H2O braking up into hydrogen and oxygen. You then bottle the oxygen, which can be used in hospitals and industry. You also bottle up the hydrogen, which is lighter than air. It was once used in airships, but proved too dangerous and was replaced by helium, which is inert. So a simple light-weight rickshaw with an electric motor, a few batteries, a hydrogen tank and hydrogen-electric converter, can have its electric power topped up all the time.

One of the major problems with electric vehicles is the batteries, which are very heavy and can limit the range and speed of the vehicle. If you want to travel at 60mph you will only get about an hour out of one charge, but at 20mph you will most likely get three hours before needing to recharge. However, if you have a constant supply of hydrogen that is being converted to electricity you can travel further - plus to top up with extra hydrogen only takes a few minutes, whereas electrically charging the batteries can take hours.

John set up a factory in the Coventry University Techno Park in Parkside, and has produced a fleet of vehicles that are now being tested. It is a shame that the original idea of helping poorer countries has now shifted to making environmentally friendly vehicles for wealthy city centres, but that is where the research money comes from.

John is also a part-time lecturer on the Design and Digital Media MA at Coventry University, and having a good background in engineering coupled with an interest in electric drive and hydrogen fuel cells allowed him to pursue his goal of designing useful urban mobility devices with zero emissions. Air quality remains problematic across the world, so the imperative is still there - and R2D2 is just a distant memory.

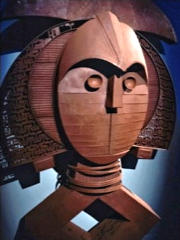

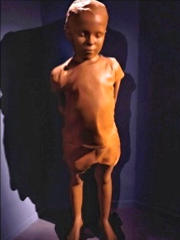

John was asked to make a sculpture using recycled aluminium for a BBC Climate Change Programme with Coventry born Roger Harrabin, the BBC climate change analyst. Four other artists were also asked to make different sculptures out of other materials, which you can see details of below.

Paul Maddocks, 2022

The Art of cutting carbonBBC environment analyst Roger Harrabin has been exploring new low-carbon technologies which could help cut those emissions He has enlisted the help of artists to tell the story. The film forms part of an exhibition at Cornwall's Eden Project, where they have curated sculptures in steel, cement, plastic, aluminium and paper. (Photos by Eden Project.) Watch "The Art of Cutting Carbon" on BBC iPlayer. |

||||

|

|

|

|

|

| Mbulu Ngulu by Kedisha Coakley made of steel. Global steel production creates 3 billion tonnes of CO2 per year. | Concrete Truths by Simon Bingle. Global concrete production creates 2.5 billion tonnes of CO2 every year. | Child Born of Oil by Gina Czarnecki. Global plastic production creates 1.8 billion tonnes of CO2 each year. | Call me Ali by John Jostins. Global aluminium production creates 0.6 billion tonnes of CO2 every year. | Cardboard Catastrophe by Simon Bingle. Global paper and cardboard production creates 0.9 billion tonnes of CO2 per year. |

Website by Rob Orland © 2002 to 2026